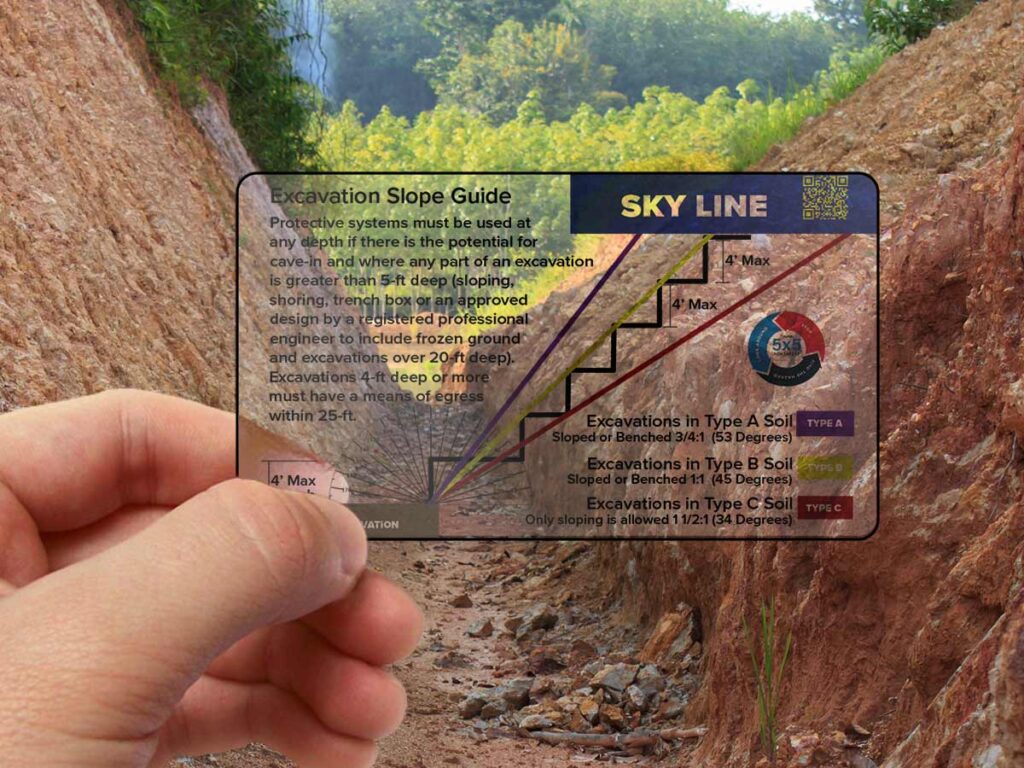

Trenches and Excavations need to be led by a competent person.

The competent person must not only have knowledge of the project and its requirements, but must have knowledge of the safety standards, be able to identify the hazards, and have the authority to correct them.

The competent person has several things to check including, but not limited to: determining the soil type, knowing whether to slope or bench the ground, knowing whether or not shoring or shielding will be required, knowing where to put the spoils, locating any encumbrances, having a means of egress every 25-ft, checking to ensure everyone involved has had training, providing barriers and/or traffic control, and knowing if an engineer needs to provide an approved system.

Before you dig, get a Pre-Excavation Safety Checklist. This form informs or reminds you of many of the things you need to check before digging including calling 811 to make sure the utilities are located and marked.

Once the Pre-Excavation Safety Checklist is filled out, a copy of it needs to be sent to the Safety Coordinator. After the form has been reviewed and approved, you will need to fill out a Trenching and Excavation Daily Inspection each day the trench or excavation is open. These also need to be sent to the Safety Coordinator each day.

In any event where the safety of those working in the trench or excavation is compromised, get everyone out until it can be made safe for re-entry.