Planning

Solutions

Construction

COMMERCIAL… IN PROGRESS

We getting started with UG Plumbing at our Ames Surgery Center. This project is a collaboration between Mary Greeley Medical Center and McFarland Clinic. We’re working with Graham Construction on this new building. Utilizing our Total Station, we’re able to triangulate all of our riser locations. Technology like this allows us to move the industry forward!

Location: Ames, IA

COMMERCIAL

The Shooting Star project in Elkhart, Iowa, is a project that ACI stepped in to help redesign to fit within the owner’s budget. The original design included a DOAS system to supply fresh air to the furnaces serving each classroom at the daycare. Once ACI joined the team, we removed the DOAS unit and installed roof-mounted supply and exhaust fans to ensure the building had the correct amount of air exchanges. Eliminating the DOAS system required an increase in the load for the furnaces to provide adequate heating to the building. When the project was finished, the ACI design team reduced the mechanical budget by almost 20%, providing a complete HVAC system that functioned efficiently. The daycare owner is now satisfied with the savings achieved.

Location: Altoona, IA

COMMERCIAL

Eight (8) in-floor heating systems were installed to maintain the comfort of Peterbilt’s truck technicians. The project included a quick-lube service bay with a walk beneath the oil pit, for which we had a dedicated exhaust and HVAC system. We installed a 20,000-gallon waste oil tank to collect used oil from the trucks. This collected waste oil is then used to fuel three (3) waste oil boilers that heat water. The full-size truck wash bay includes in-floor heat, exhaust, and radiant heat. Finally, the new location has a dynamometer for tuning and servicing Peterbilt trucks, and ACI installed its specialty exhaust system.

Location: Ankeny, IA

Contract amount was $2,121,000.

EDUCATION

ACI Mechanical was involved in the new Ames High School building project. Our engineers, technicians, and administrative staff completed the project on time and within budget, working over two years and 55,000 field hours. The project involved fabricating and installing HVAC ductwork, chillers, and hydronic piping.

Location: Ames, IA

Contract amount $19,345,200.

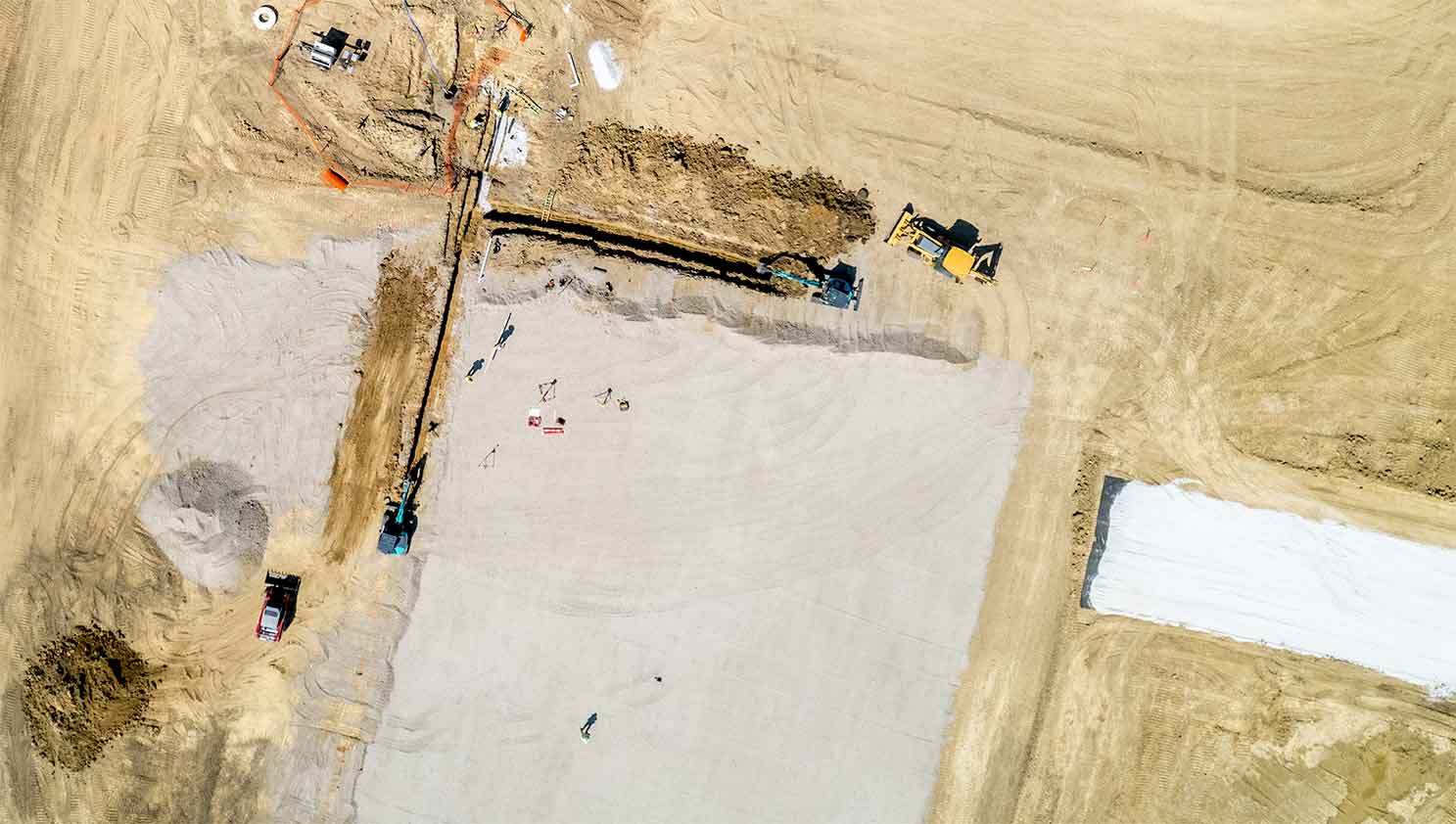

INDUSTRIAL

Altus Commerce Center in Altoona, IA, is a campus comprised of three large warehouse shell buildings totaling 1,091,434 square feet. ACI Mechanical is responsible for the plumbing and HVAC installation in each building. Two of the three buildings are nearing completion; building A, which is 265,700 square feet, is already finished, and building C, the largest at 497,587 square feet, is almost complete, as ACI is performing the final installation of HVAC equipment. The last building, building B, which is 328,147 square feet, is currently under construction.

Location: Altoona, IA

Contract amount $1,222,000.

INFRASTRUCTURE

ACI Mechanical has put together a team of skilled engineers, encompassing civil, structural, landscaping, and specialty subcontractors. Their objective is to present a $17.3 million guaranteed maximum price (GMP) and construction methodology to HAS. The proposal describes the installation of a new overhead piping system with a routing plan and support structures, replacing the previous one.

Location: Houston, TX

INDUSTRIAL

ACI Mechanical has been awarded the contract for the Mechanical portion of a project worth $9 million. They have successfully completed the detailed layout drawings required for the installation. The company has installed a total of 90,000 pounds of galvanized and stainless steel ductwork, 29 air handling units and 10,000 feet of Hydronic Piping. The facility is state-of-the-art and fully temperature-controlled, featuring redundant air handling systems with HEPA filter housing. The building waste system has been designed to be contained in storage tanks before being transferred to the process waste building so as to ensure that the environment is not exposed to potentially dangerous and contagious pathogens.

Location: Ames, IA

EDUCATION

An efficiency upgrade was performed on the mechanical systems serving the main areas of Boone High School. ACI replaced two chillers and condensing units in the school’s east wing, six air handling units, and twelve VAVs to deliver clean and conditioned air to classrooms. Finally, a new pool dehumidification unit was installed to ensure that the pool is a more enjoyable space. With the addition of new ductwork, piping, and controls, the retrofit at Boone High School was a significant efficiency upgrade.

Location: Boone, IA

MORE

PROJECTS

Iowa State University Marston Hall – Ames, Iowa

ACI Mechanical utilized the delay to BIM model the mechanical systems. A constant flow of field measurements was transferred back to our modeling team. The model produced a coordinated layout, enabling our manufacturing facility to prefabricate four floors of ductwork and HVAC piping mains and branch lines. Extensive prefabrication reduced our rough-in durations by two weeks per floor, allowing the finishing trades an equal head start.